NEXT SDR40 Saddle Roof

NEXT SDR40 Saddle Roof

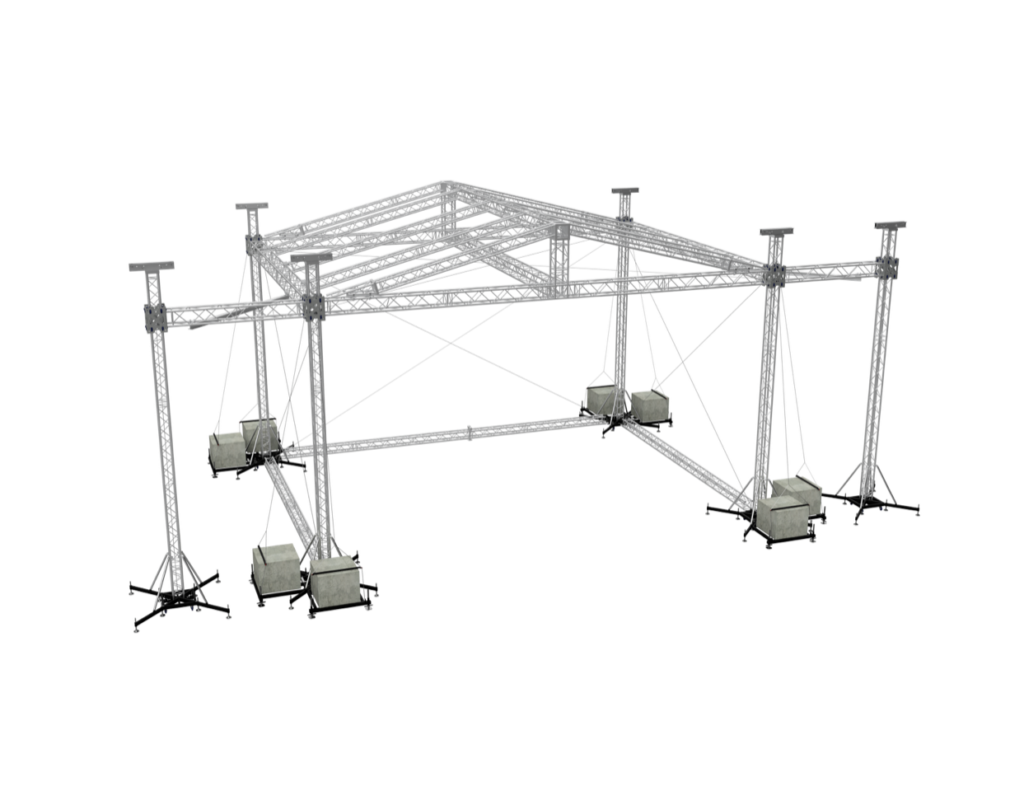

The SDR40 roof is ideally suited for concerts and outdoor events. This medium-sized roof is available in two sizes; 10×8 and 12×10 meters. The pitched design allows water to drain from the canopy, the roof is based on 4 self-climbing towers. The main rig exists out of NH44 truss combined with NH44/34 truss as roof structure, combined with some special parts. All roofs are standard included with a top canopy, tensioning gear and guiding wires, an extended manual and structural report.

Facts

- Quick & easy setup

- Scalable and versatile

- The ideal solution for small and medium-sized events

- Options for expansion and upgrade are available

Product information

The SDR40 Saddle Roof is the bigger brother of the SDR30 roof, de 8×10 meter size is overlapping on both series. But within the SDR40 series, a 12×10 meter variant is available. The saddle roof meets all the required international standards and is available in two sizes; 10×8 & 12×10 meters. The roof is designed to be built on stand-alone steel bases, the roof can be lifted with a hoist that is attached to the sleeve block which slides over the NH34 tower. Since the ground supports and additional parts for the roof are mainly constructed from standard NH34/44 parts, only a few special roof parts are needed to build an SDR40 roof. This makes the roof very attractive and cost-effective.

Ballast Tray

Even with small roof constructions a huge amount of ballast is necessary. To activate the ballast in the right way is not easy. A solution to activate the ballast is a so-called ballast tray. A ballast tray (NT-BASE-BF02) is a platform to be used in combination with a standard base (BASE 02). If the ballast tray is attached to the base the platform can carry up to 2000kg. A cable set (NT-CS-BF02) will activate the ballast against lift and sliding. For standard roof construction, build with compression beams and with two ballast trays for every tower the ballast can be adequately added to the construction.

Motor House

A common way of using an electric chain hoist is to attach the hoist on top of a truss next to the tower and attach the hook on the other side of the tower to the sleeve block. Another way is to use a so-called “motor house” which will be assembled on the sleeve block and can carry and attach the chain hoist’. When using a motor house, the rig can climb closer to the top of the tower.

International Standards

The standards of the design are based on recent Eurocodes 1,3 & 9, these are high standard European norms for Structures made out of aluminum or steel. In addition, all our constructions and products are built according to the EN 1090 EXC2 principle. These standards are recognized worldwide, some countries and locations require an addition.

Canopy & Sidewalls

Standard the canopies are grey on the outside and black on the inside, these are also available completely black. For the sidewalls mesh is also available, fire retardant canopy and mesh walls are available on request.

Ballast

The needed ballast per tower depends on the size and the roof configuration:

- Canopies, is the roof only covered with the top, or with the back wall, or complete with sidewalls?

- Bases, with compression or stand-alone bases

- Anti-slip material between bases and substrate

- Weight of load or stage integration

Wind Control

The SDR30 has a maximum wind speed of 17.8m/s or, 64km/h – 40mph*, this calculation is valid when all the canopies are installed. If the winds reach this speed or above the side and back walls should be removed, after that the Out of Use cables should be attached. At this point the construction can hold upwind speeds up to 28.0m/s – 100km/h – 62mph*

*(maximum speed of wind gusts)